From Idea Sketch to Scalable Product: The One Stack Approach Explained

Introduction

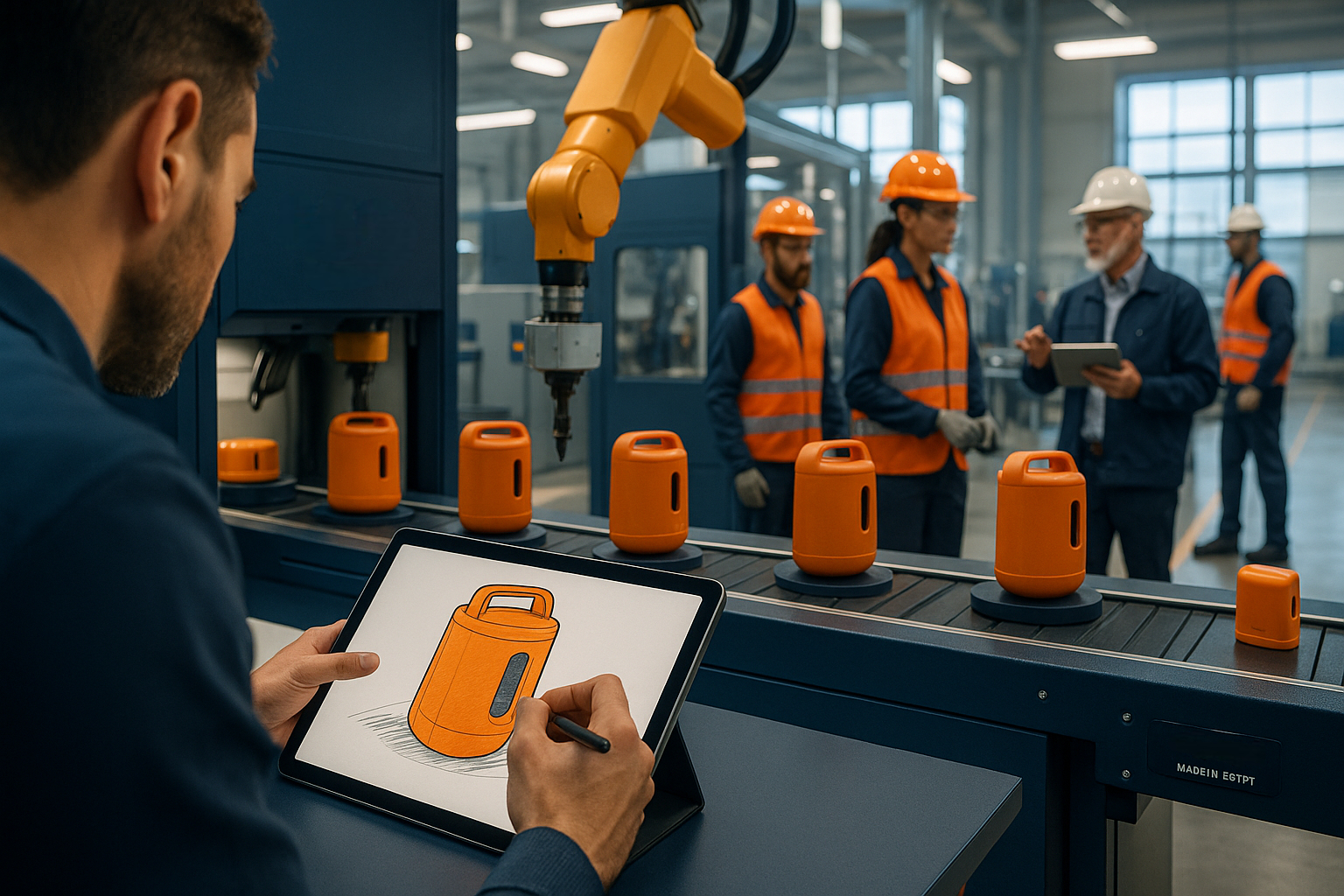

Every successful product begins as a simple idea — a sketch on paper, a concept in a notebook, or an insight born from a market gap. Yet, turning that idea into a scalable, high-quality product is one of the greatest challenges faced by modern innovators. The journey from concept to production often involves navigating complex supplier networks, managing multiple design iterations, and ensuring cost efficiency without compromising quality.

For entrepreneurs, startups, and established brands alike, the difference between success and stagnation lies in the ability to move quickly and confidently through the product development process. This is where the One Stack approach shines. By integrating design, prototyping, and manufacturing under one unified system, One Stack eliminates unnecessary complexity and empowers creators to bring their products to market faster and smarter.

This article explores the complete journey from idea sketch to scalable product, detailing each stage of the One Stack process. You will learn how clarity, speed, and control combine to create a manufacturing experience that supports innovation at every level.

The Evolving Landscape of Product Development

Product development today is defined by speed, customization, and global competition. Companies that thrive are those that can turn ideas into market-ready products efficiently and reliably.

Rising Expectations and Compressed Timelines

Customers expect rapid innovation and consistent quality. Market cycles are shorter than ever, leaving little room for delay. Businesses need partners that can move quickly from concept to production without sacrificing precision.

Globalization and Supply Chain Complexity

While globalization opens opportunities, it also introduces risk. Managing multiple suppliers across borders increases the likelihood of miscommunication, delays, and inconsistent standards. Integrated manufacturing solutions, like the One Stack approach, reduce these risks by consolidating accountability.

The Shift Toward Localized Manufacturing

Many brands are rediscovering the benefits of local manufacturing. Egypt, for example, has emerged as a strategic hub offering cost efficiency and skilled labor. One Stack leverages this advantage to deliver world-class products proudly made in Egypt.

Understanding this evolving context is essential for recognizing why an integrated approach to product development is no longer optional — it’s strategic.

Inside the One Stack Approach

The One Stack approach transforms product ideas into tangible outcomes through four structured stages, ensuring full visibility and control at every step.

Stage 1: Data Gathering

Every project begins with comprehensive data collection — market research, technical requirements, and material specifications. This foundation ensures that decisions are informed, reducing costly revisions later. One Stack collaborates closely with clients to define objectives, constraints, and desired outcomes.

Stage 2: Design and Modeling

Once data is secured, the design team transforms ideas into detailed 3D models. This stage includes iterative feedback loops, ensuring alignment with client vision. Advanced CAD tools and simulation software validate structural integrity and performance before production begins.

Stage 3: Samples and Prototypes

Prototyping bridges concept and reality. Through rapid prototyping and material testing, One Stack refines designs to achieve optimal manufacturability. This phase ensures that every product not only looks good but performs reliably in real-world conditions.

Stage 4: Production and Scaling

After validation, the product enters full-scale production across One Stack’s network of over 200 certified factories. Centralized project management guarantees quality, timeline adherence, and transparency from the first unit to mass production.

This structured methodology ensures clarity, speed, and control — the hallmarks of the One Stack process.

Common Challenges in Product Development

Despite technological advances, companies still face recurring challenges when bringing products to market. Recognizing these obstacles helps innovators plan more effectively.

Fragmented Supplier Networks

Managing multiple vendors often leads to communication gaps, inconsistent standards, and unclear accountability. An integrated partner model eliminates these issues by serving as a single point of contact.

Unclear Cost Structures

Hidden costs and fluctuating supplier quotes can derail budgets. One Stack addresses this through transparent pricing and clear deliverables, allowing businesses to plan confidently.

Quality Control and Compliance

Maintaining consistent quality across production runs is critical. Certified factories, standardized processes, and rigorous inspection systems ensure that each product meets international standards.

Scaling from Prototype to Production

Transitioning from prototype to large-scale manufacturing often exposes design inefficiencies. The One Stack approach mitigates this risk by validating manufacturability early in the design phase.

By addressing these challenges proactively, organizations gain a competitive edge in both speed and reliability.

Strategies for Seamless Product Development

To navigate complexity, successful companies apply structured strategies that integrate design, engineering, and manufacturing from the start.

Cross-Functional Collaboration

Product success depends on alignment between design, engineering, and production teams. Regular communication ensures that creative intent aligns with technical feasibility, reducing rework.

Data-Driven Decision Making

Accurate data informs better choices. From material selection to production scheduling, One Stack uses data analytics to optimize cost, performance, and sustainability.

Prototyping as a Learning Tool

Each prototype provides valuable insights. Iterative testing helps identify design flaws early, saving time and money. Rapid feedback cycles accelerate innovation.

Digital Integration and Traceability

Modern manufacturing thrives on transparency. Digital dashboards track every stage, enabling real-time monitoring and performance optimization.

These strategies align closely with the One Stack philosophy — combining clarity and control to achieve predictable outcomes.

Implementing the One Stack Framework

Adopting a unified product development framework requires both process discipline and cultural alignment.

Step 1: Define Clear Objectives

Start with clarity. Identify market needs, performance targets, and key success metrics. This ensures every stakeholder shares the same vision from the beginning.

Step 2: Integrate Teams Early

Early integration prevents downstream issues. Involving engineers and manufacturers during design discussions ensures practical feasibility and cost efficiency.

Step 3: Validate and Iterate

Continuous validation is critical. Use prototypes and simulations to test assumptions. Each iteration refines the product until it meets both functional and aesthetic goals.

Step 4: Manage Production with Precision

Once the product is ready for manufacturing, process control becomes essential. One Stack’s centralized management ensures consistency across multiple factories, maintaining both quality and schedule integrity.

Following this structured framework leads to faster launches, fewer surprises, and stronger product-market fit.

Best Practices for Scalable Product Success

Building scalability into your product strategy from day one sets the foundation for long-term growth and resilience.

Design for Manufacturability

Scalable production begins with design decisions. Simplify component counts, standardize materials, and ensure easy assembly. These choices reduce production complexity and costs.

Establish Quality Benchmarks Early

Define measurable quality standards during design. Doing so ensures that every supplier and process aligns with the same expectations, reducing defects downstream.

Build Supplier Partnerships, Not Transactions

Long-term relationships with trusted manufacturing partners create stability. One Stack’s single-partner model fosters accountability and consistent performance over time.

Leverage Local Manufacturing Advantages

Egypt’s manufacturing sector offers a strategic balance between cost efficiency and craftsmanship. Partnering locally enhances agility while supporting national industry growth.

Scalability is not achieved by chance; it’s built through deliberate design, strong partnerships, and continuous improvement.

The Future of Integrated Manufacturing

As technology evolves, the integration of design, data, and production will redefine how products are made and scaled globally.

Smart Manufacturing and Automation

Artificial intelligence and robotics are transforming factories into intelligent systems. Predictive analytics, automated inspection, and adaptive production lines are becoming standard practice.

Sustainability as a Competitive Advantage

Eco-conscious design is no longer optional. Manufacturers that minimize waste and energy consumption gain both ethical and market advantages. One Stack integrates sustainable practices into every project stage.

Customization at Scale

Emerging technologies allow for mass customization — producing unique products efficiently. Flexible production networks, such as those coordinated by One Stack, make this possible.

The future belongs to those who embrace integration, transparency, and innovation as core principles of manufacturing excellence.

Conclusion

Transforming an idea sketch into a scalable, market-ready product is a journey that demands precision, collaboration, and trust. The One Stack approach simplifies this path by providing a single, integrated system that combines design, prototyping, and production under one roof.

By focusing on data-driven decisions, cross-functional alignment, and local manufacturing excellence, One Stack empowers innovators to bring products to life with clarity, speed, and control. Whether you are a startup founder or a global brand, adopting an integrated manufacturing partner can redefine how you approach product development.

The future of product creation lies in seamless collaboration and smart execution. As manufacturing continues to evolve, those who embrace unified frameworks like One Stack’s will not only innovate faster but also build products that stand the test of time.